Plywood vs Melamine: What to Choose for Wood Panel Products?

Selecting materials for furniture, cabinetry, or interior décor?

Plywood and melamine are two common materials for wood panel products. Known for their popularity and versatility. They can be used in cabinets in the kitchen, laundry, or bathroom. In short, everywhere.

But what is the difference between plywood and melamine? What qualities sets them apart? And which one is the better option?

At Ply Supply, we help Perth cabinet makers, carpenters and DIY enthusiasts. To choose the best material according to the needs of project.

In this guide, we’ll present a comparative overview of plywood vs melamine. Their unique features, uses, benefits, and disadvantages. So, you can make an informed choice with all the needed information.

Let’s get started with learning what plywood is.

What is Plywood?

Plywood is a lightweight and highly versatile material. That is commonly used in construction, furniture, cabinetry, and DIY crafts.

Made from thin layers of timber veneers. Plywood is bonded together using heat, pressure, and adhesive. The result is a sturdy and durable panel. Each layer, or ‘ply,’ is arranged in alternating grain directions, creating a cross-grained structure.

This construction process enhances plywood’s durability and makes it highly resistant to cracking and warping. It’s used in a wide range of applications. E.g.

- Custom cabinetry

- Flat-pack furniture

- Residential interiors

- Commercial interiors

- Hobby projects

- Wall cladding

Plywood’s natural charm and versatile properties make it a perfect choice. For all kinds of design and building needs.

How is Plywood Made?

Plywood manufacture consists of the following steps.

- It begins with the careful selection and harvesting of timber.

- Logs are stripped of their bark and sliced into thin sheets called veneers.

- These veneers are then dried to remove excess moisture for effective bonding.

- Once dried, the veneers are stacked in alternating grain directions.

- A cross-grained structure is made to reduce the risk of warping or cracking.

- The layers are then bonded together using heat, pressure, and strong adhesive.

- And lastly, the bonded sheets are trimmed, sanded, and graded for specific requirements.

This structured manufacturing process guarantees plywood’s versatility and durability.

Why is Plywood Best for Construction and Cabinetry?

Plywood is one of the most versatile building materials. Its unique cross-grain structure provides a strong and durable foundation. And used in construction, cabinetry, and furniture.

It is available in various dimensions, thicknesses, and plywood grades. Hence, you can easily find the right plywood panels for any of your woodworking projects. E.g. Marine-grade plywood is perfect for high-humidity environments like kitchens and bathrooms.

Know more about Plywood Grades

So, whether you’re building furniture or designing interiors. Plywood offers the strength and beauty needed to create long-lasting results.

Pros of Plywood

Numerous advantages of plywood make it a popular choice in various industries.

- High strength-to-weight ratio and excellent impact resistance.

- Natural wood finish enhances the beauty of cabinetry and furniture.

- Withstand daily wear and tear in the kitchen or other high-traffic areas.

- Available in various thicknesses and grades to suit different projects.

- Holds up under stress and supports the load-bearing structures.

- Low chances of shrinking or warping as compared to solid wood.

- Lightweight and easier to handle.

- Can be shaped to fit curved surfaces.

- Excellent sound reflector.

- Can be painted or stained to match any design needs.

Cons of Plywood

Plywood has many benefits but don’t forget some of its drawbacks too.

- More expensive than melamine.

- Difficult to cut without splintering or cracking.

- Painting requires preparation and can be time-consuming.

Now, let’s move towards melamine.

What is Melamine?

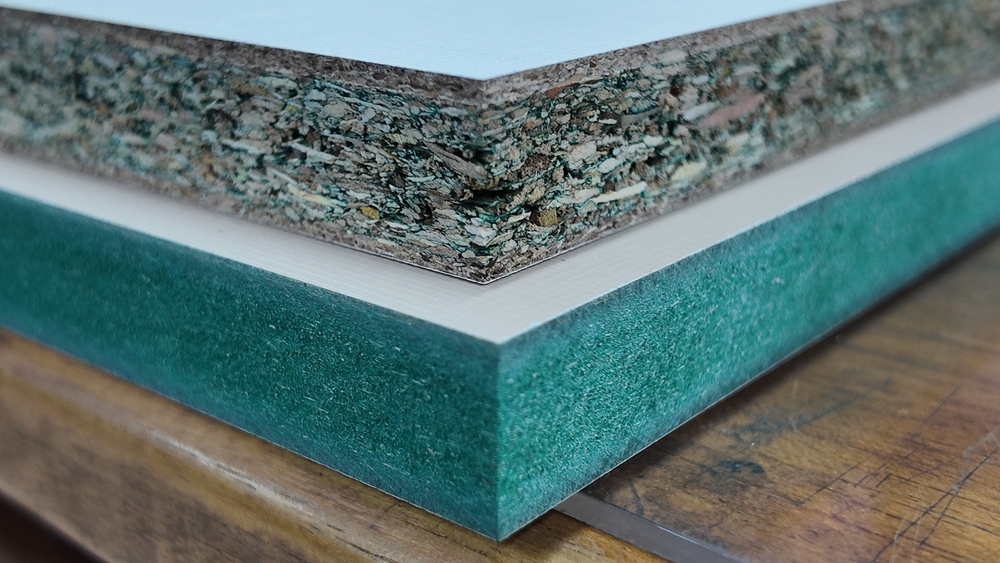

Melamine is a durable and cost-effective wood composite material. That combines the strength of MDF (Medium Density Fiberboard) or particleboard. With a protective melamine resin coating.

This resin layer enhances its resistance to moisture, stains, and everyday wear. Thus, making it a popular choice for:

- Furniture

- Cabinetry

- Interior design

- Commercial decor

- Industrial applications

Moreover, it also offers affordability and stylish finishes.

How is Melamine Made?

Unlike plywood, which is constructed using timber veneers, melamine is made by bonding a thin layer of resin to the surface of MDF or particleboard. This creates a smooth and visually appealing finish.

- The production of melamine starts with a core material. E.g. MDF or particleboard.

- A thin layer of melamine resin is applied to the surface using heat and pressure.

- This process creates a hard, glossy, or matte finish. Resistant to scratches and stains.

- The resin coating is customised with various colours, patterns, and textures.

- Wood grain designs are made to mimic the appearance of cabinet timbers.

This versatility makes melamine to create modern designs. At a fraction of the cost of solid wood.

Why Melamine is Great for Furniture and Interior Design

Melamine is celebrated for its versatility, durability, and affordability. It is available in a wide variety of finishes. From glossy and matte to wood grain patterns. Which gives designers and homeowners endless options to choose from.

Moreover, melamine’s flame-retardant properties add an extra layer of safety. Especially in environments where fire resistance is important.

Pros of Melamine

- Scratch and moisture-resistant, ideal for wet areas like kitchens.

- Affordable and light on the pocket.

- Lower flame spread rate.

- Easy to cut or shape with the right tools.

- Easy to clean and doesn’t require sealing or special care.

Cons of Melamine

- Melamine resin can release Volatile Organic Compounds (VOCs). Affecting indoor air quality.

- Fades over time if exposed to direct sunlight or harsh cleaning chemicals.

- Less rigid than plywood and can warp or bend under heavy loads.

- Prone to scratches and dents.

- Heavier than plywood, making handling and installation more challenging.

- Difficult to repair if it gets damaged or scratched.

Key Differences Between Plywood and Melamine | A Quick Comparison

| Feature | Plywood | Melamine |

| Material Composition | Layers of timber veneers glued in alternating grain directions | MDF or particleboard coated with a melamine resin |

| Strength & Durability | Strong, durable Resistant to cracking and warping | Durable but less rigid Possibility of warping or bending |

| Cost | Expensive, especially for high-grade plywood | Cost-effective, offering a budget-friendly option |

| Weight | Lighter Easier to handle and install | Heavier Difficult to handle and install |

| Moisture Resistance | Only marine-grade plywood is moisture-resistant | Highly moisture-resistant Suitable for bathrooms, kitchens, and laundry areas |

| Aesthetic Variety | Natural wood finish Can be painted to suit different design needs | Available in a wide range of colours, textures, and wood-look finishes |

| Ease of Cutting & Shaping | Difficult to cut Needs special techniques | Easier to cut and shape DIY-friendly |

| Environmental Impact | Low VOC emissions But concern is present with some grades of plywood | Release VOCs in high amounts Affect indoor air quality. |

| Best Uses | Ideal for high-stress projects that need strength | Suitable for less load-bearing environments |

| Maintenance & Care | Needs maintenance When exposed to moisture or heavy use | Easy to maintain Smooth and durable surface that resists stains and scratches |

| Flame Resistance | Not inherently fire-resistant Though some grades offer it | Offers better fire resistance |

| Painting & Finishing | Can be painted But needs proper preparation for it. | Ready-to-use finishes No need for additional painting or staining. |

Final Word

So, which material takes the crown in plywood vs melamine debate? The truth is, it all depends on your project.

For affordable and easy-to-maintain interiors, melamine is the best choice. But if you need a material with strength, flexibility, and an elegant natural finish. Plywood is the way to go.

Searching high-quality plywood for your cabinetry or construction project?

Shop Durable Plywood and Cabinet Timber at Ply Supply

We have a range of high-quality cabinet plywood with H2S Termite Treatment. Available in different colours, styles and grades. That can guarantee the durability of your cabinetry and even timber flat-pack furniture.

Whether you need structural, non-structural or hardwood plywood. We have the perfect piece of plywood for your cabinetry projects.

Don’t settle for less. Upgrade your projects with the best plywood on the market.