What is Formply? Plywood for Concrete Formwork

Imagine a plywood so tough, smooth, and water-resistant. That can handle concrete like a pro. That’s formply for you!

It’s not your run-of-the-mill wood sheet. It’s designed to give you strong walls, beams, and bridges you’d be proud to drive over.

And guess what? At Ply Supply, we’ve got it for you. From F17 Formply to other graded formply supplies, we stock the best of the best. Building a skyscraper or working on DIY furniture? You can count on us to deliver products having quality and sustainability.

Let us guide you about the formply manufacture & uses.

What is Formply?

Formply is engineered plywood designed for use in concrete formwork. It is also known as formwork plywood. The top layer of phenolic film not only provides water resistance but also doesn’t let the concrete stick to the surface. This allows for easy removal of the plywood after the concrete has set.

It is used for:

- Construction of large civil structures

- Heavy-duty concrete formwork

- High-load infrastructure projects

Let’s see how its construction helps in supporting such a wide range of structures.

How Plywood for Concrete Formwork is Manufactured?

Manufactured from high-quality veneers glued together with durable adhesives. Formply Australia is widely recognised for its strength and reliability.

Unlike usual plywood, it has a laminated face on both sides. That gives it additional qualities and strength. The laminated sheets are made of a plywood core. And high-density overlay of impregnated paper around it.

Premium-grade phenolic resin is used as a lamination glue between sheets. Furthermore, A-type marine bonding is used in it, the strongest plywood bond available. This creates a strong sheet of material that doesn’t crack by nails of construction. And is less likely to shrink or warp during use.

The type-A bond glue also withstands temperature changes and moisture. It keeps formply sheets sound & durable even in wet conditions or water submersion. Read on to find out its characteristics in detail.

Characteristics of Formply

Understanding the features of formply is essential to make the right choice for your project. Its important characteristics include:

1. Compliance with Australian Standards

All formply available through Ply Supply adheres to Australian standard AS 6669. This guarantees its safety and reliability for construction applications. Meeting these standards means formply is durable enough for long-term performance.

2. Water-Proof

The phenolic film coating makes formply resistant to water absorption. This feature prevents warping and maintains the integrity of the plywood. So, it survives easily even in wet concrete, water submersion, or humid conditions.

3. Weather Resistant

Formply is built to endure harsh weather conditions. Including heavy rain, extreme heat, harsh sunlight, and freezing temperatures. This resilience makes it suitable for outdoor construction projects and infrastructure development.

4. Load Bearing Capacity

Its engineered structure with double lamination gives formply a high load-bearing capacity. Enabling it to support the weight of construction structures and wet concrete. It doesn’t deform or crack even under the load of a building.

5. Resistant to Wear & Tear

Construction sites are demanding environments, but formply is built to last. Its A-type glue keeps it intact for years of heavy usage. So, it resists everyday damage and allows multiple reuses over time.

6. Range of Colours

Formply comes in a variety of colours, such as black, brown, or red. So, its sheets can be used in visible locations and suited to any building colour theme. The aesthetic appeal of colours further enhances the value of it.

7. Smooth Finish

The smooth, film-coated surface makes the concrete retain a flawless finish. This reduces the need for additional sanding or finishing on surface. Saving time and labour effort and managing the budget of your project.

8. Cost-Effective

Thanks to its durability, long-term application, and reusability. Formply represents excellent value for your money. Builders can use it multiple times, reducing the overall cost of materials for building formwork.

Now let us guide you on how to choose a formply for your project.

Factors to Consider While Choosing Formply

Choosing the right formply for your specific project involves several key factors. Important ones are:

1. Quality and Durability

Look for formply that meets Australian standards and is made from high-quality veneers. The longevity of your formply is a must-have quality. Especially for large-scale projects where formply is to be reused multiple times.

2. Environmental Impact

Sustainability is a growing concern in construction. Go for sustainable formwork plywood to reduce the environmental footprint of your project. At Ply Supply, we prioritise eco-friendly materials that balance quality with sustainability.

3. Thickness Grade

Selecting the correct thickness is essential for project success. Check the grade and thickness level of your formply. And make sure that it is able to handle the load demands of your project.

Types of Formply

There are several variants of formply available in the market. Each with its own strength and ideal use case. Let’s discuss them one by one.

Type | Features | Ideal For |

MDO Plywood (Medium Density Overlay) | A resin-treated fiber overlay on the plywood surface. Smooth & paintable surface and moderate water resistance. | Signage, general construction, and where a clean finish is required |

Phenolic Plywood | Durable phenolic film coating Resists moisture and wear exceptionally well | High-reuse concrete formwork, outdoor construction, and heavy-duty applications |

Film Faced Plywood | A tough & resin-impregnated film bonded to its surface Water-resistant & smooth | Slabs, beams, and industrial formwork structures |

Each of these types have something unique to offer. Be it smoother finishes or higher resistance to certain elements. But when it comes to strength, durability, and reusability, F17 Formply 1800 x 1200mm 17mm stands out as a top choice. Let’s get to know it in detail.

F17 Formply | A Sustainable Formwork Plywood

F17 Formply is one of the most popular grades of formply due to its impressive strength and durability. Its F17 rating means it has 17mm thick laminations and it can handle significant loads. Making it suitable for demanding applications like large infrastructure projects.

Be it a bridge or multi-storey building. F17 formply can do the weight-bearing job safely and efficiently for you.

Specifications of F17 Formply

Thickness | 17mm |

Dimensions | 1800 x 1200mm |

Wood | Eucalyptus & walnut |

Coating | Phenolic film (both faces) |

Coating weight | 240 gr/m2 |

Edges | Grey sealing |

Strength Rating | F17 |

Reusability | High |

Glue bond | A bond (Exterior) |

Standard | AS/NZS 6669 |

At Ply Supply, we are offering two pricing options for it:

- Lose price: 59.00$

- Pack price: 2240.00$

Get F17 Structural Certificated Formply 1800x1200x17mm Now

Available in various grades, thicknesses, and finishes. F-17 formply caters to diverse applications from large-scale commercial builds to smaller home projects.

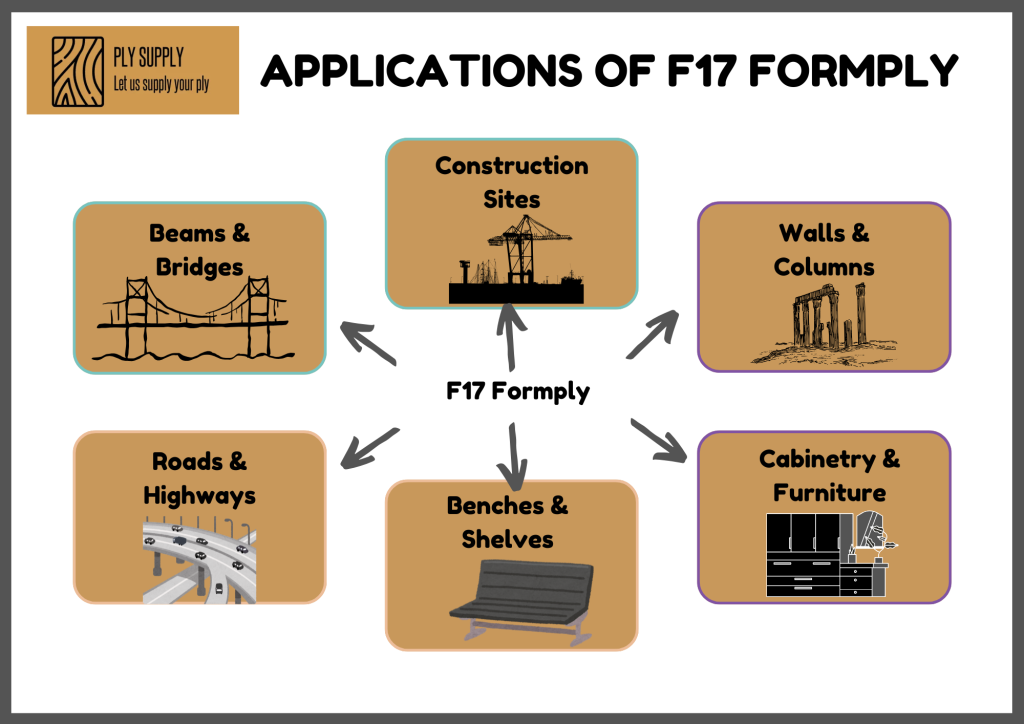

Applications of F17 Formply

Formply is highly versatile and used across a wide range of industries and projects.

Application | Description |

Mould for Concrete on Construction Sites | Used for moulding concrete, creating precise shapes for slabs, walls, and other elements. |

Walls and Columns | Provides smooth surfaces for clean & professional finishes in vertical concrete structures. |

Beams and Bridges | Its strength makes it suitable for supporting heavy loads in large-scale infrastructure projects. |

Roads and Highways | Commonly used to form components like barriers or retaining walls in road construction. |

Cabinetry and Furniture | Durable and smooth finish makes it ideal for high-quality furniture applications. |

Benches or Shelves | Offers a durable and smooth base for functional and decorative uses, like benches or shelving units. |

Now, let’s move toward some maintenance tips for your formply sheets.Top of Form

How to Extend the Life of Your Formply? 11 Tips

With proper care, you can significantly extend the lifespan of your formply. Some tips from our side are:

- Store on a levelled ground to avoid deflection of long sheets.

- Do not move the formply pallets after removing the strapping.

- Fill any gaps between the laminated veneers with putty and seal the edges.

- Use an edge sealant to paint unprotected edges and drill holes.

- Clean thoroughly after use and remove concrete residue to prevent surface damage.

- Store formply in a well-ventilated, moisture-free environment to avoid warping or rot.

- Apply a release agent or formwork oil to prevent concrete from sticking. Use soapy water before to make cleaning easier.

- Use plastic or nylon tools to minimise the surface damage of your formply.

- Regularly check for cracks or chips. Inspect the damage and repair minor issues immediately.

- Repair small scratches and fill any holes with mastic or epoxy filler.

- Rotate panels and keep alternating between sheets to reduce concentrated wear and extend their usability.

Want to Buy Formply Online for Your Next Project?

Build Smarter with Ply Supply’s F17 Formwork Plywood

Ply Supply is your premier formwork supplier in Western Australia. We offer only the best materials for your construction needs. From F17 Formwork Plywood to sustainable formwork plywood. Our range is designed to cater to diverse applications.

We’ve done the hard work of sourcing reliable, high-quality products. So you can focus on what matters – delivering outstanding results. Let us help you build better, smarter, and more sustainably.