What is LVL Timber | Easy Guide to Laminated Veneer Lumber

Laminated veneer lumber (LVL) is becoming a go-to material for builders and DIYers in Perth.

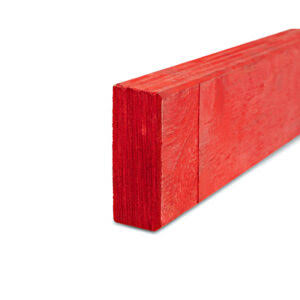

As a modern alternative to traditional timber beams, LVL timber is prized for its reliability and consistency. It is much stronger, straighter and more uniform than regular sawn timber.

In this guide, we’ll explore what LVL timber is, how this engineered lumber is made. Additionally, we’ll discuss LVL’s impressive strength, durability and benefits. You’ll learn about common LVL sizes and dimensions as well. So, without any further ado, let’s get into it.

What Does LVL Stand For?

In building plans and material lists, LVL stands for Laminated Veneer Lumber. In other words, timber LVL is just another way to refer to laminated veneer lumber beams. This edge-to-edge lamination is what gives LVL its name.

In practice, calling something “an LVL beam” simply means a laminated veneer lumber beam.

What Is LVL Timber?

LVL timber (Laminated Veneer Lumber) is an engineered structural wood product. It is made by bonding many thin wood veneers together with a moisture-resistant adhesive, then pressing them under heat.

All the wood grains in the laminations run lengthwise which gives the beam uniform strength and stiffness.

In plain terms, LVL is like a giant glued-up board. Like a very wide piece of plywood with all layers aligned. This design makes it far more uniform. In fact, LVL is stronger, straighter, and much less likely than conventional lumber to warp, twist, bow or shrink.

Key Features of LVL Timber | What Make LVL the Best Choice

Understanding the unique characteristics of laminated veneer lumber (LVL) can help you make smarter choices for your next project.

Highly Strong & Lightweight

One of the top reasons Perth builders choose LVL timber is its impressive strength-to-weight ratio. It’s strong enough to rival steel in structural performance. But still, it’s light and easy to work with. This makes it ideal for carrying heavy loads across wide spans. Additionally, LVL is less likely to shrink, sag or split. This means fewer headaches down the line.

Consistently Straight and Stable

Sick of warped or twisted beams slowing down your build? With timber LVL, that’s rarely a problem. Its engineered construction; layer upon layer of wood bonded together, makes it reliably straight.

Easy to Handle, Quick to Install

Working with LVL timber is refreshingly simple. It’s lighter than most hardwood. This means it can be installed without cranes or heavy lifting gear. Perfect for speeding up your build.

Built for Longer Spans and Bigger Ideas

LVL beams can be manufactured in much longer lengths. Like mostly up to 13.2 metres, or even more on request. That means fewer joins, less waste, and more freedom in your LVL design.

How Is Laminated Veneer Lumber (LVL) Made?

Manufacturing LVL is an industrial process that involves several precise steps:

- Veneer Production – Logs (typically softwoods like pine, fir or spruce) are rotary-peeled to create thin veneers about 3 mm thick.

- Drying – The veneers are dried to a low moisture content (mostly under 10%) to make them stable and prevent warping later.

- Adhesive Bonding – A waterproof adhesive (usually phenol-formaldehyde resin) is applied to each veneer sheet.

- Assembly and Pressing – The glued veneers are stacked with all grains parallel. And the pile is pressed under high heat (around 200–230°C). This cures the glue and bonds the layers into large solid panels (often called billets).

- Cutting and Sizing – Finally, the cured LVL panels are cut or trimmed into beams and boards of the required size. Because LVL is made in continuous panels, the length is only limited by manufacturing and transport. Factory presses can produce panels up to roughly 6 feet wide and 80 feet long (about 24 meters).

Benefits of LVL Timber

LVL offers a host of advantages over regular sawn timber. For example:

Exceptional Strength

LVL beams are extremely durable. They carry heavy loads relative to their weight, making them one of the strongest wood-based materials relative to its density.

Termite Resistance

Perth is a high-risk termite area. So, LVL beams are mostly ordered with glue-line H2S termite treatment. Like at Ply Supply, we stock premium H2S-treated LVL to protect structures from pests and moisture.

Dimensional Stability

The laminated construction makes LVL very stable. It is much less prone to warping, twisting or shrinking than conventional lumber. This means LVL beams hold their shape and performance over time, giving you confidence in your build.

Consistent Performance

Each LVL beam is manufactured to exact specifications. All pieces meet strict design grades. So, the quality and load capacity are uniform across your project.

Long Spans & Versatility

LVL can span longer distances than the equivalent solid timber. This allows for open-plan designs with fewer support posts. LVL is used for everything from floor joists and roof rafters to heavy load-bearing beams, lintels and formwork. This reduces the need for extra columns.

Sustainable & Cost-Effective

LVL is made from fast-growing plantation pine. The manufacturing process uses almost all of the wood which minimise waste. Over time, LVL’s durability and longevity can save money by reducing maintenance and replacements.

LVL Timber Sizes & Common LVL Lumber Dimensions

-

684 left in stock

PLYLVL11- Structural 90×45 E11 F11 H2S Treated

$39.95 – $49.85Price range: $39.95 through $49.85Rated 0 out of 5 -

60 left in stock

-

24 left in stock

-

40 left in stock

-

204 left in stock

PLYLVL14- Structural 240×45 E14 F17 H2S Treated

$115.20 – $172.00Price range: $115.20 through $172.00Rated 0 out of 5 -

340 left in stock

PLYLVL14- Structural 200×45 E14 F17 H2S Treated

$96.00 – $120.00Price range: $96.00 through $120.00Rated 0 out of 5 -

184 left in stock

PLYLVL14- Structural 150×45 E14 F17 H2S Treated

$76.00 – $94.99Price range: $76.00 through $94.99Rated 0 out of 5 -

220 left in stock

-

70 left in stock

LVL beams come in many standard sizes. Common LVL timber sizes have depths (heights) such as 90 mm, 140 mm, 190 mm, 240 mm or 300 mm, paired with widths of 45 mm, 63 mm or 75 mm.

For example, at Ply Supply, we stock popular sections like 90×45, 150×45 and 240×63 mm. Heavy-duty beams go up to 450×75 mm.

By convention, LVL sections are named by depth × width in millimeters.

For instance, LVL 240×45 means 240 mm deep and 45 mm wide. Some suppliers’ size charts list beams like 170×35, 200×45, 240×63 and 300×63 mm for their H2/H2S-rated LVL range.

Lengths are typically 4.8–6.0 m for stock beams, matching standard truck sizes.

Because LVL is made in continuous panels. Manufacturers can also produce much longer lengths on request. Factory presses can create LVL panels up to 6 ft wide and 80 ft long. In practice, many suppliers offer LVL beams up to 8 m, 10 m or 12 m as special orders.

Always check with your supplier for exact LVL lumber dimensions available.

Common Uses of LVL Timber

LVL’s strength and consistency make it ideal for many structural roles. Common LVL applications include:

- Beams and Rafters – LVL is frequently used as main support beams, roof rafters and floor joists in both houses and commercial buildings.

- Lintels and Headers – LVL beams are placed over doors, windows or removed walls to carry loads safely.

- Trusses and Columns – In roof trusses, LVL can serve as chord members or purlins, and it also makes strong load-bearing posts and portal frames.

- Formwork and Flooring – Bright-yellow H2S-treated LVL panels are common for concrete formwork. LVL I-joist flanges and rimboards are other specialized uses.

Beyond standard beams, LVL offers design flexibility. Wide LVL panels (1.2 m) allow custom LVL design elements like curved or angled beams. Advanced products like cross-banded LVL (with alternating laminations) provide extra shear strength for highly loaded members, though these are usually special-order items.

Explore Our Termite-Treated LVLs at Ply Supply

Have a quick look at below-given table showcasing the available Laminated Veneer Lumber LVLs at Ply Supply, along with their specifications (grades) and pricing.

Product | Dimensions (mm) | Grade & Treatment | Price | Link |

LVL Formwork | 150 x 77 | H2S | $132.00 | |

LVL Formwork | 95 x 45 | E11 / H2S | $54.00 | |

LVL Formwork | 95 x 65 | E11 / H2S | $90.00 | |

Structural LVL Beam | 150 x 45 | E14 F17 / H2S | $76.00 | |

PlyLVL Structural | 200 x 45 | E14 F17 / H2S | $107.25 | |

Structural LVL | 240 x 45 | E14 F17 / H2S | $115.20 – $172.00 | |

PlyLVL Structural | 240 x 63 | E14 F17 / H2S | $288.00 | |

Structural LVL | 300 x 45 | E14 F17 / H2S | $211.68 | |

Structural LVL | 300 x 63 | E14 F17 / H2S | $330.00 | |

PlyLVL Structural | 90 x 45 | E14 F17 / H2S | $57.36 – $71.70 |

For more information about our LVL products, find SPAN TABLE here.

Looking for top-quality LVL beams in Perth? And wondering where to find quality LVL timber suppliers

You won’t have to search far for LVL timber in Western Australia.

At Ply Supply, we stock a full range of termite-resistant LVL beams in all standard sizes. By choosing a reputable LVL supplier, you ensure your LVL is certified and high-performance.

Shop Premium LVL Timber Now at Ply Supply

Get expert advice on selecting the right LVL grade and dimensions for your project. Browse our LVL category and keep your build strong, stable and on budget.

FAQs About LVL

Q1: Is LVL stronger than solid wood?

Yes, LVL is generally stronger than solid wood. Especially over long spans. Its layered construction enhances strength and minimises weaknesses.

Q2: How does LVL hold up against moisture?

LVL is more moisture-resistant than traditional wood. But it should still be protected from excessive moisture exposure, especially in outdoor applications.

Q3: Can LVL be painted or stained?

LVL can be painted or stained. Although a high-quality sealant is recommended to maintain its appearance and protection.

Q4: How much weight can an LVL beam support?

The weight capacity of an LVL beam depends on its dimensions. For instance, an I-beam with a 5-inch depth, a 3-inch flange width, and a flange thickness of 0.326 inches can typically support 10 pounds per foot.

Q5: Can LVL beams get wet?

It’s best to keep LVL beam dry during and after construction to avoid moisture damage. Sealing the ends and edges helps protect against water. But for long-term exposure, it’s recommended to apply a preservative treatment and a protective coating.

Q6: How can I protect LVL beams from water?

To protect LVL from moisture:

- avoid water exposure

- seal the ends and edges

- apply a preservative treatment along with a protective coating

Q7: What is the lifespan of LVL timber?

In dry, internal conditions where wood moisture content stays below 20%, LVL can meet durability standards for up to 50 years.

Q8: Is LVL eco-friendly?

Yes, LVL is considered an eco-friendly building material due to its efficient use of wood resources and reduced waste.